Diesel engines boast impressive durability, efficiency and longevity, but as they get older, they require more care and attention to continue providing reliable service. Keep reading for useful advice about caring for and prolonging the life of an aging marine diesel engine.

Diesel engines are efficient, durable and the engine of choice for heavy equipment and boats. If you’re a boat operator, you’re probably no stranger to diesel engine fuel problems. It’s important to know the signs of trouble as soon as they begin.

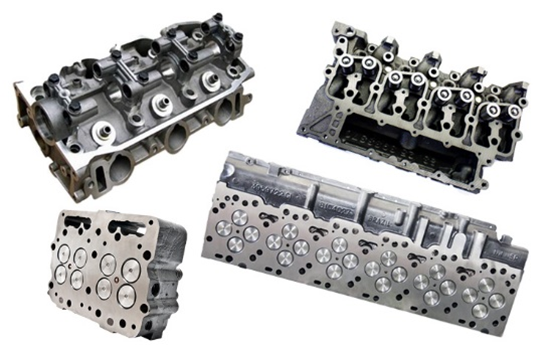

The diesel cylinder head in your engine probably doesn’t get a lot of attention until you notice a problem with your boat’s performance. Without cylinder heads, there’d be no pressure seal within engine cylinders or the internal combustion that powers modern engines.

Often we don’t realise just how dependant we are on our cars until something happens to them. Depending on what the exact problems are, repairs can be very costly, particularly if they have anything to do with the engine. This is one of the reasons why reconditioned engine parts are becoming a popular alternative for car owners everywhere because if fitted properly, they can make your engine run as good as new.

Automobile engines are complicated mechanisms that are made up of several internal parts that work like clockwork to produce that power that moves your vehicle. In order for the engine to operate properly it needs all of its parts to be in good condition. One fault can be disastrous! Let's take a look at the main parts of the engine.

The question of buying a flywheel versus a flexplate is an important one. These two components serve vital functions and help marine engines run smoothly. That means telling the difference and knowing when they need to be replaced is critical.

Your diesel engine needs to stay at a reasonable temperature to work properly. When it overheats, it can cause reduced performance or a complete failure, resulting in a replacement. If your diesel engine overheats, you can find the problem and get everything running again. Discover how to diagnose diesel engine overheating in boats.

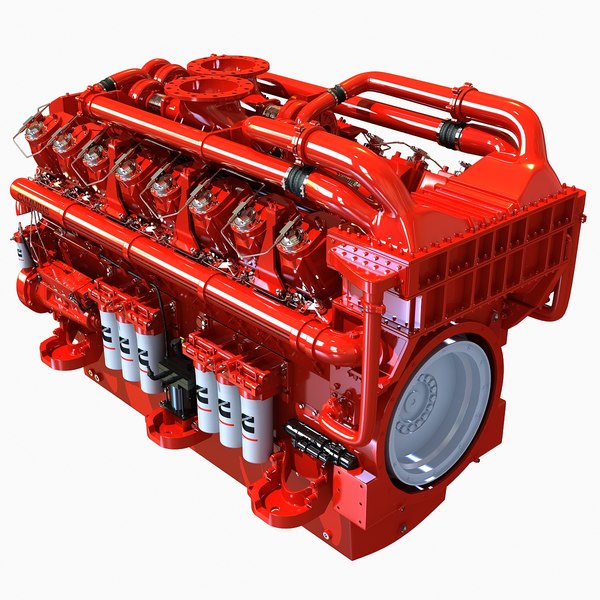

Whether it’s powering a forklift, a boat or an 18-wheeler, diesel engines are vital to ongoing performance. Regular maintenance can keep it running well for years to come, regardless if it is a new diesel engine or an old one that needs a little more TLC.

Your cylinder head is an important part of your engine. It is part of the combustion chamber where fuel and air flow through and exhaust flows out. If problems with your cylinder head are not addressed, it can cause your engine to go bad. If this happens, often the best thing to do is replace it. But how can you tell if your cylinder head is in need of replacement?

From shipping trucks and school buses to yachts and cargo ships, diesel engines power many of the world’s vehicles. Diesel engines in boats, trains and trucks transport goods and products all over the world — roughly 94% of freight is shipped in diesel-powered vehicles. Heavy-duty equipment on farms and construction sites is typically powered by diesel engines. Military vehicles and industrial facilities employ diesel engines, as well. Diesel engines are also common in passenger cars, especially in Europe.