Series B is a series of four-cycle diesel engines with four or six cylinders of “one litter per cylinder” capacity, which Cummins has developed for use in automotive, agriculture, power generation and marine applications. They developed the 4BT engine series as a way to promote the heavy duty work of these engines.

The engine of the Cummins B-Series is a straight six-cylinder diesel engine from Cummins Engine, built since 1984. Since then, the engine has been constantly evolving; the capacity has been increased from 5.9 to 6.7 litters. Designed as an industrial engine for use in commercial vehicles, the B-Series gained notoriety through its use in Ram pickup trucks from 1989 onwards. The B Series was manufactured by Consolidated Diesel Company of North Carolina. With an average mileage of 482,803 km up to the first engine overhaul, the B-Series in Ram Trucks is considered durable. In the following section, the first engine of the B-series, type 6BT, will be discussed.

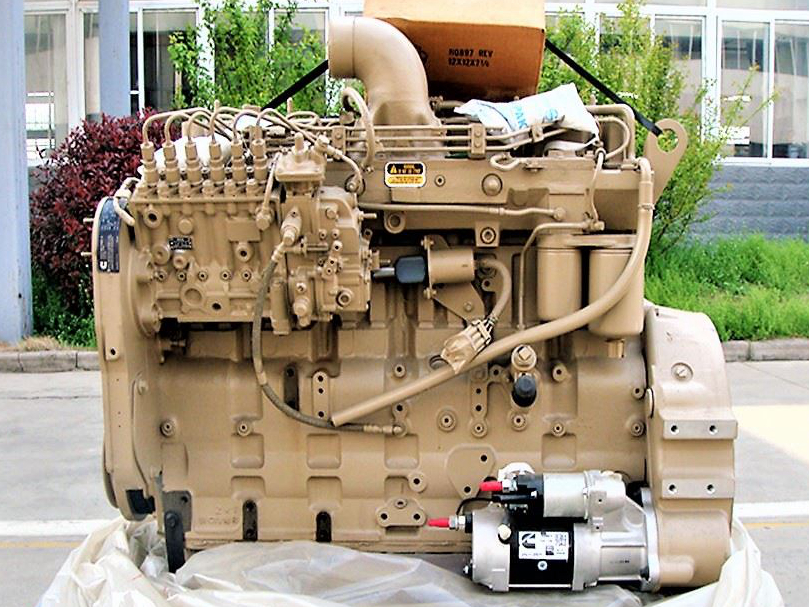

One of the heaviest duty engines that have seen the most use is the Cummins 6CT engine from the C-series that the company manufactures. when you take a look at motor homes, RVs, fire trucks, large pickup trucks, and other big vehicles, then what you are seeing under the hood is probably a Cummins 6CT engine. This heavy duty engine definitely has seen a lot of use due to its reliability and the horsepower that it provides. And both of the qualities of the C-series of an engine have made the 6CT a very popular one among the people who love customizing car engines and parts.

You cannot deny the fact that Cummins engine assembly seems like a daunting task, especially if this is your first time doing it. There are a lot of factors that you need to consider, and assembling a Cummins engine requires a lot of patience in the process. So, to help you get started here is a complete guide to assembling.

A HOWO TH7 rolled off the assembly line at China National Heavy Duty Truck Group, also known as Sinotruk, on Tuesday, marking the 500,000th model produced and sold this year for the heavy-duty truck manufacturer.

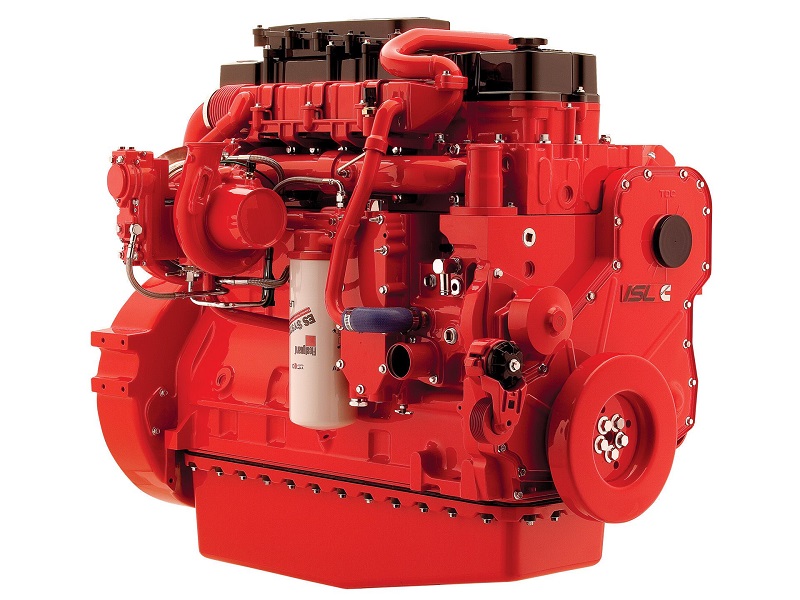

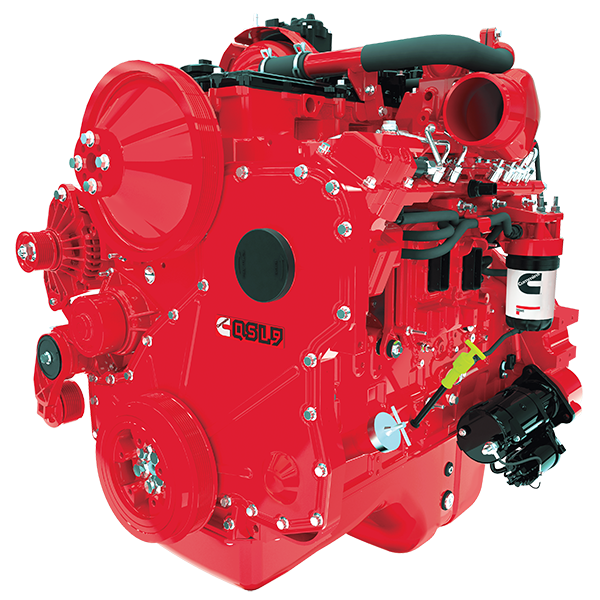

Are you planning to buy a Cummins ISLe parts for your automobile? But, you do not have any idea on what are the important things that you have to consider when choosing the one that you can buy? And to help you with that, you can read the list below that shows what these important things are.

Are you in the market for replacement diesel parts? If so then you should consider QSL parts. The Indiana-based company has existed for nearly a century and is a Fortune 500 company that’s become a leader in the market.

Sometimes boat owners think they can skimp out on replacing an outdated thermostat. While a thermostat is a small part of a marine engine, it is crucial for the engine’s overall health. Due to its importance, it’s critical not to discount the value of monitoring your thermostat and replacing it when needed to ensure your engine runs at its top performance.

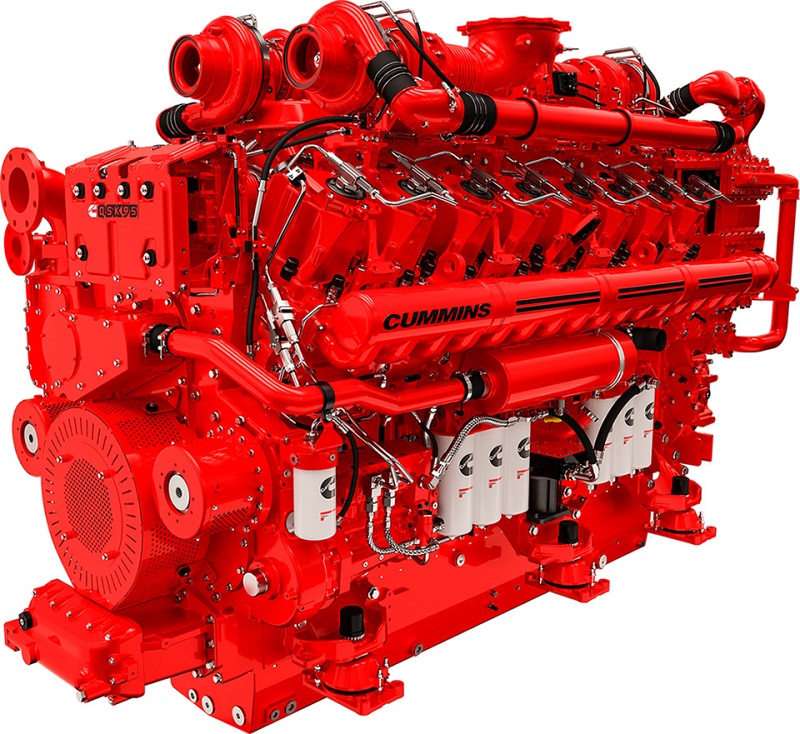

The Cummins QSK95 rules the seas. It’s one of the largest diesel engines available globally. Many marine boats throughout the world are already using the engine’s incredible power for various applications. Alongside its power, the QSK95 is designed for minimized environmental impact, which is attractive to many environmentally conscious companies.

When you work with a marine engine every day, the most important task is doing everything you can to keep all its components up and running. One of these main components is the aftercooler. This device can manage air temperature on diesel engines for boats.